How do you make ceramics?

3 August 2019

Contact Us

Boisbriand

654 Curé-Boivin

Boisbriand, Quebec

J7G 2A7

Monday to Friday: 9 AM to 5 PM

Saturday: 9 AM to 5 PM

Phone: +1 450-419-5111

Email: [email protected]

Saint-Laurent

3850 Boulevard Côte-Vertu West

Saint-Laurent, Quebec

H4R 1V4

Monday: Closed

Tuesday to Saturday: 9 AM to 5 PM

Phone: +1 514-500-9866

Email: [email protected]

What is ceramics, its origin? How do you make ceramics?

Ceramics are a material made from clay dug from the ground, mixed with water to make it soft and flexible, and also combined with other natural materials (which we will discuss later). It is crushed and then fired at a high temperature in a large industrial kiln.

We can also define ceramics as an inorganic, non-metallic solid composed of metallic or non-metallic compounds that have been shaped and then hardened by heating to a high temperature. In general, they are hard, corrosion-resistant, and brittle.

The word “ceramics” comes from Sanskrit and means “to burn.”

This process—digging the raw material from the ground, adding water, shaping, and firing—has been used to make ceramics for thousands of years.

Archaeologists have discovered ceramics made by humans dating back at least 24,000 years BC. These ceramics were found in Czechoslovakia and took the form of animal and human figurines, tiles, and balls.

Since these ancient times, the technology and applications of ceramics have constantly advanced. We often take for granted the significant role that ceramics have played in human progress.

Ceramic manufacturing has evolved significantly.

How is ceramics processed?

Ceramics are used to make commercial products of various sizes, shapes, details, complexity, composition, structure, and costs.

As mentioned earlier, ceramics are generally produced by applying heat to treated clays and other natural raw materials to form a rigid product.

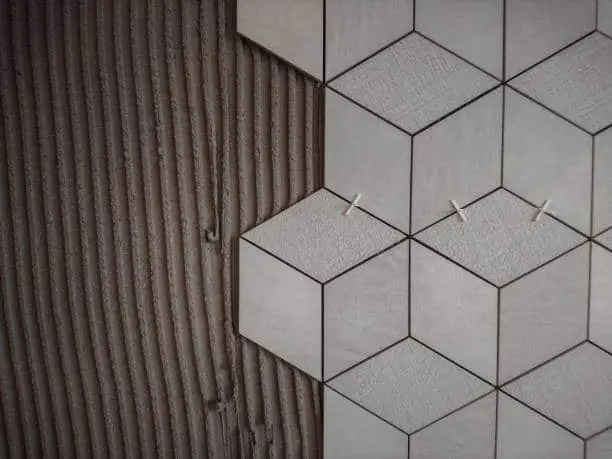

Next comes the transformation of ceramic particles into a desired shape by adding water and/or additives such as binders, followed by a shaping process.

Common shaping methods for ceramics include extrusion, slip casting, pressing, tape casting, and injection molding. Once the particles are formed, these “green” ceramics undergo a thermal treatment (called firing or sintering) to produce a finished rigid product.

What are the properties of ceramics?

The properties of ceramic materials, like all materials, are determined by the types of atoms present, the types of bonds between atoms, and how the atoms are packed. This is known as the atomic-scale structure. Most ceramics are composed of two or more elements. This is called a compound. For example, alumina (Al2O3) is a compound consisting of aluminum and oxygen atoms.

Due to the wide range of properties of ceramic materials, they are used for a multitude of applications. In general, most ceramics are: hard thermal insulators, wear-resistant, brittle, refractory, electrical insulators, non-magnetic, oxidation-resistant, subject to thermal shock, and chemically stable.