Countertops Manufacturing

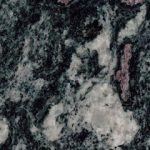

- Kitchen and bathroom countertops exist in a spectrum of colors, designs and surfaces. The manufacturing process for each of these varies and is often responsible for the resulting product. Grifon brings to you several countertop options which are durable, cost-effective, and easy to care for. Naturally occurring materials like marble, granite and quartz are good options. Some consumers also use ceramic tile for the countertops but these a more prone to damage since individual tiles can chip or crack with time.

Grifon manufactures countertops with sustainability in mind. We try to reduce our carbon footprint in the existing ecological system so that our users can choose environment friendly products through us.

The process of manufacturing countertops involves sourcing the materials and designing them to suit your requirements. We manufacture standard sizes and we also deal in countertops that are made to order. So if you are looking for a customized countertop that enhances the beauty of your kitchen or bathroom them talk to us for design options.

Whether you are renovating your home or buying countertops for a new home, our designers can help you pick the best countertop which meets your bathroom or kitchen’s style and design.

- Top Quality

All raw materials and finished products available at Grifon are sourced from suppliers who deal in high quality products. This is because we believe in producing the best products that can be made available in the market for our customers.

- Pocket-friendly Pricing

High quality does not really mean that you will end up paying huge prices. We price all our products reasonably so that you can enjoy good quality products at an affordable rate.

- Highly Experienced Professionals

From consulting a store salesperson before choosing a countertop to having our professionals install the countertops and seal them for you, you will notice that every Grifon representative that you meet is an experienced professional who strives to provide high quality customer experience.

The polished beautiful granite quartz or marble countertops undergoes an extensive process of stone fabrication to achieve the finished product.

the fabricator will inspect your chosen slabs. Stone often contains characteristics indigenous to that particular material, similar to how individuals may be born with birthmarks.

The templates are also arranged to ensure appropriate flow for the various countertops in your layout. As an example with an L shaped countertop, or a countertop and an island that is parallel or perpendicular, you want to ensure the overall flow of the countertop pattern will work in your finished project.

CUTING THE STONE

The bridge saw cuts with a diamond segmented blade, and cuts at a feed rate of approximately 7 feet per minute. The water jet cuts with high pressure water with garnet particulate suspended in the water at a feed rate of 1 foot per minute.

CUTING THE STONE

By nature, those thinner pieces are not as strong as a larger surface area of stone. we work on the best method for increasing the flexual strength of stone, specifically to reinforce this thin area.

When the granite arrives to the fabricator from the quarry, the face of slab is already polished. Typically the granite face is not polished or changed at the fabricator’s shop. What does need polished, however, is the edge.

During this step, the edges of the stone ground to remove the microchipping and achieve the best and tightest seam possible. This gives you a finished product where the seam should fit nicely together.

By applying one coat of sealer, we take that rate up to 97%. Both the edges and face of the stone are sealed during this step. Since sealer doesn’t degrade in an interior setting, it is pretty much a set it and forget it step.